JVPP Series

The non-mechanically designed seals/glands of this pump makes operating them ridiculously easy. It can also provide effluent treatment plans which can increase your efficiency.

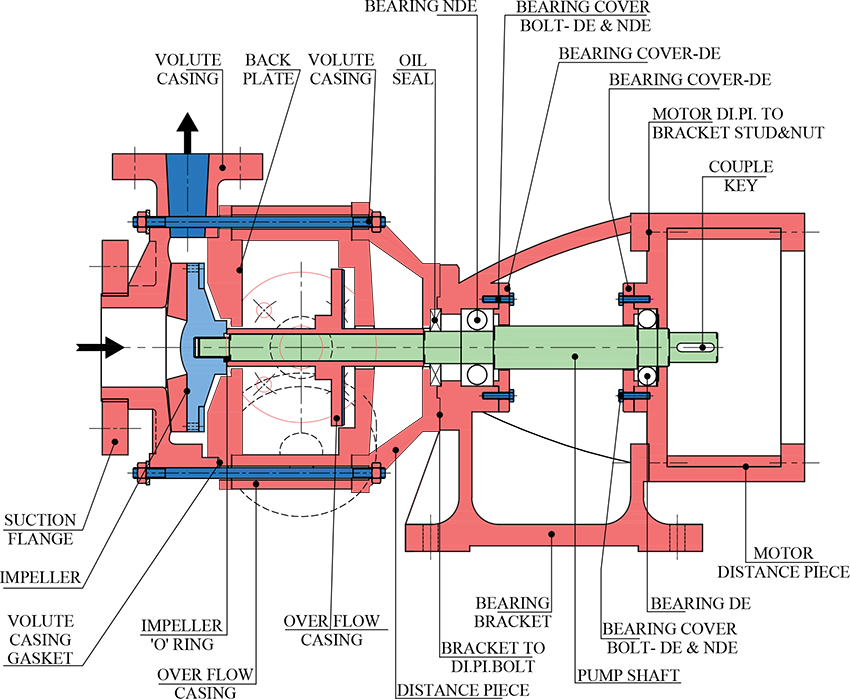

Pump Construction

Expeller

Solid injection moulded polypropylene prevents liquid from going further up which channelizes it through the outlet of the overflow chamber.

Backplate

Made with thick walled solid injection moulded polypropylene.

Volute Casing

Top centerline discharge, self venting volute casing formed out injection moulded polypropylene.

Impeller

All impellers are precision moulded, light in weight, a semi open construction with large, contoured flow passages for maximum handling of the liquid.

Bearing frame

Made from heavy cast iron which is built to accommodate vertical flange type motor & for a wall hung installation.

Ball Bearing

The single and double row ball bearing is shouldered & locked on a shaft with locknuts and washer, and in bearing housing which can carry radially and any unbalanced thrust load.

Shaft

Made from En Steel, these shafts are protected with a polypropylene sleeve which does not come in contact with process media.

Overflow Chamber

Large injection moulded a polypropylene chamber guide’s excess liquid back to the sump eliminating the need for a shaft seal.

Priming Chamber

The solution for suction left application

They are ideal for JPP and JPPL series pumps. Priming Chamber to suit customer requirements for other models available on request.

The JEE Priming Chamber is used for priming the pump in the event of negative suction condition. This avoids the need of foot value and frequent priming of the pump.

The priming pot is connected to the pump suction which is filled with liquid and sealed airtight before the initial start up. After starting the pump, the liquid from priming pot is drawn into the pump and partial vacuum is created in the pot. Due to partial vacuum, the liquid rises in the suction pipe and pushes the air into the pot. This fills the suction pipe which results in priming. The air accumulated in the priming pot mixes with liquid and is driven through discharge of the pump.

Features

Applications

| Effluent treatment plants |

Dyes and intermediate steel rolling mills |

All types of industrial application |

| Filter press feeding |

Slurry transfer |

Ceramic, ETP & STP |

| Paper & Pulp |

Sugar & food |

Eva-operator and scrubber application |

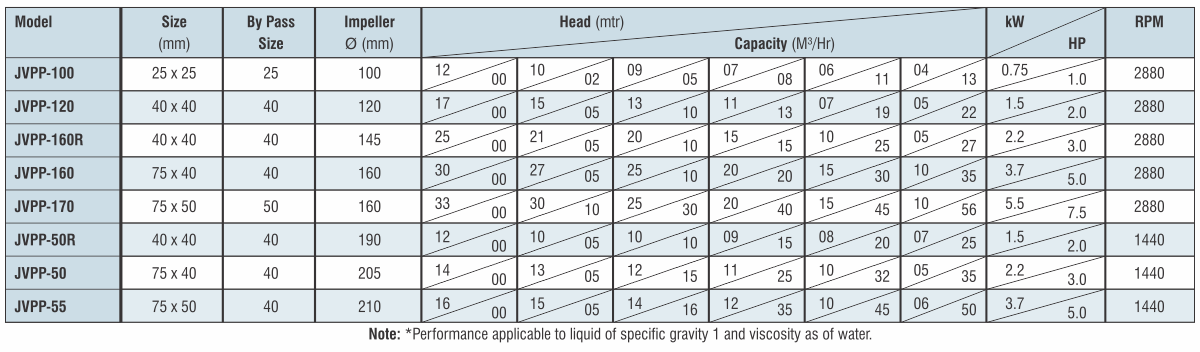

Performance Chart

Operating Data

| Capacity | Up to 300 m³/hr |

| Head | Up to 65 Mtr. |

| Discharge Size | 50 mm to 100 mm. |

| Temperature | Up to 80°C |

| Speed | Up to 3500 rpm |

| Pressure | Up to 6.5 kg/cm2 |

| M.O.C. | PP, UHMWPE |