Installing an AODD mining pumps is a simple process that requires minimal effort. Attach the suction and discharge fittings to start, and your pump is ready.

Individuals working in the mining sector know the importance of pumps and how challenging their work would be without them. One such type of pump crucial in mining operations is the air-operated double-diaphragm (AODD) pump. AODD pumps play a vital role in maintaining productivity and safety in various applications, from coal mining to hard rock, and are considered essential equipment in the mining industry.

Mining pumps, such as AODD pumps, are utilized in nearly all types of mining operations, including open-pit, underground, rummaging, and in-situ processes that involve soft/hard rock, coal, phosphate, exquisite metals (e.g., gold, copper, nickel, silver), and diamond. Although underground mining utilizes the highest number of AODD pumps, these pumps are used regularly across all four types of mining. Whether it’s in the slope, drift, or face, mining pumps play a crucial role in maintaining the safety of miners.

Opting for an air-operated double-diaphragm (AODD) pump can simplify the pumping process, which could otherwise be complex. Therefore, seeking assistance from manufacturers and distributors is advisable to enhance your comprehension of AODD pumping fundamentals. Equipped with this knowledge and answers to frequently asked questions, you can effectively utilize an AODD pump for different mining purposes.

This article will examine the most frequently asked questions concerning AODD pumps in mining applications.

What are the possible applications of AODD pumps in mining?

Apart from dewatering and ore processing, the most prevalent uses of water pumps, there are several other ways to utilize the pump in mining operations. These include transporting chemicals and fluids for equipment upkeep, purification, shotcrete pumping, pumping explosives, etc.

What Are the Most Suitable Pump Materials for Mining?

Maintenance managers and process engineers who operate in mining are familiar with pump specifications, such as the appropriate size and flow rate for AODD industrial pumps. However, selecting the ideal pump materials can be ambiguous. Therefore, the answer to this query is conditional on the type of fluids being pumped.

If the task is dewatering, the acidity of the mine water is the primary determinant. Conversely, if the pump is utilized above ground on the process side, the corrosiveness of the chemicals is the most crucial consideration.

Despite the complexity of the decision, a manufacturer or distributor representative can aid in selecting the correct pump body and elastomer materials by considering the fluid’s characteristics.

When selecting pump materials, various fluid factors must be taken into account, such as

- PH level

- Abrasiveness

- Temperature,

- Thickness

Additionally, mobility requirements are also significant. Depending on the fluid being pumped, a lighter pump material such as polypropylene or aluminum may be preferred over a heavier cast iron option.

Can AODD Pumps be Moved Easily?

Certainly, AODD pumps provide exceptional mobility, exceeding the convenience provided by electric and centrifugal pumps. Please refer to the previous question for advice on choosing the ideal pump material for a portable pump. The primary advantage of industrial AODD pumps in comparison to other pump types, as long there is air, you have an air source, and you can relocate the pump without necessitating the assistance of an electrician or technician.

Can AODD Pumps Be Utilized Safely in Mining?

Absolutely. AODD pumps are ideal for mining operations as they are air-operated, eliminating the need for electricity, which can be hazardous in damp or potentially explosive environments like mines.

Several applications, including coal mining, require pumps that have attained the ATEX certification. The European ATEX standard must be complied with for equipment used in explosive surroundings. AODD pumps adhere to the ATEX regulations, which means they meet rigorous safety criteria.

Is The Flow Rate of AODD Pumps Adjustable?

Indeed, the flow rates of AODD pumps can be modified according to your requirements. For instance, if the mine has high water flow or minimal seepage, you can adjust the pump’s speed accordingly. For a 3-inch pump, it is possible to operate it at rates ranging from 15 to 280 gallons per minute, which is a capability that many other pump types lack. In addition, you can regulate the flow by reducing the air given to the pump or closing the discharge valve.

Is it Feasible to Utilize AODD Pumps in Arid Conditions?

AODD pumps can perform proficiently in dry conditions without mechanical seals since they use diaphragms to move the liquid back and forth. In addition, it is noteworthy that running an industrial AODD pump dry does not generate heat in the pump, which eliminates the risk of damaging the seals that could arise if an electric submersible pump were operated in the same manner. Nonetheless, running the pumps continuously in a dry state is not advisable since the internal components will undergo wear as if the pump were being used commonly.

Is It Possible for AODD Pumps to Manage Solids, Suspended Solids, and Slurries?

Certainly, diaphragm pumps are capable of handling solids, slurries, and suspended solids in varying mixtures and viscosities. To determine the ideal pump for your specific application, consult with one of our knowledgeable distributors.

Can AODD Pumps Function When Operating Against a Closed Valve or Dead Head?

The pump stops cycling once the discharge pressure surpasses the air input pressure. However, once you release the tension on the discharge side, the pump will begin cycling again.

Steps to Enhance the Lifespan of An AODD Mining Pump.

You can implement various measures to enhance the durability of your AODD mining pump. Firstly, it is crucial to manage the quality of the air that goes into the pump, as air in the mines is often moist or polluted. In addition, improving the compressed air source can increase the dependability and longevity of the pump’s air side.

On the fluid side, the primary concern is diaphragm longevity. It is necessary to avoid starving the pump to ensure the durability of the diaphragm. Thus, the suction hose must be the same size or more significant than the pump. You can add a suction screen to prevent debris from entering the pump, but it is necessary to clear any blockages regularly to increase the diaphragm’s lifespan.

Another approach to extend your pump’s life is to avoid running it 24/7. Although an AODD pump can operate dry, each cycle creates wear and tear on the valve and diaphragms, decreasing lifespan.

Lastly, it is essential to remember that industrial mining pumps, such as AODD pumps, are more efficient at discharging fluid than sucking it in. Therefore, it is advantageous to reduce the length of the suction line. You can compensate for it in the discharge line if you need to cover more distance. Long suction lines can reduce diaphragm life and prevent the pump from priming.

What is The Cost of An AODD Pump for Mining?

The cost of an AODD pump for mining is influenced by factors such as the pump size, material, style (ball-valve or flap-valve), and the market you are in. To find the right pump that fits your budget, you can consult a reliable local distributor who can assist in selecting the appropriate pump.

Is Running and maintaining an AODD Pump at a Higher Air Volume more expensive?

The answer is yes. Since AODD pumps are positive displacement pumps, they lose efficiency if running at their maximum capacity. Choosing the right pump for the specific application is crucial to optimize pump performance. Selecting a bigger pump and operating it at a slower pace is recommended rather than choosing a smaller pump and running it faster. While a larger pump may have a higher initial cost, it provides the best return on investment regarding longevity and reduced air consumption.

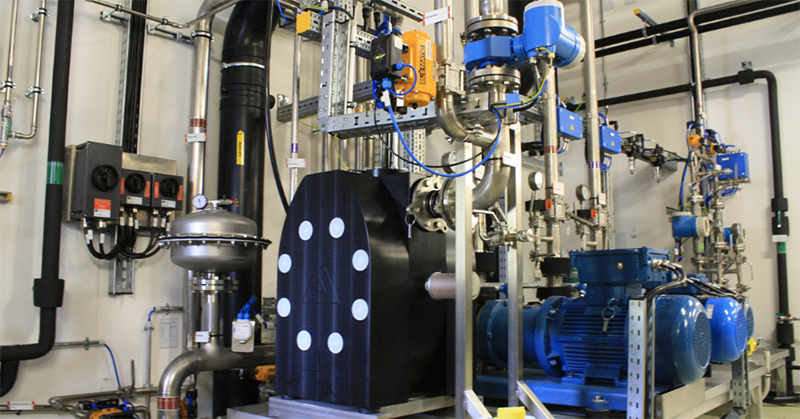

Could the Installation of an AODD Pump Be Difficult?

Installing an AODD mining pump is a simple process that requires minimal effort. Attach the suction and discharge fittings to start, and your pump is ready. You don’t need specialized certifications or involve electricians or other technicians. The only control you may need is an optional valve.

Moreover, your local distributor can assist with the installation, given their experience and expertise in mining applications. They can also recommend additional accessories, such as filters, regulators, hoses, screens, valves, and more, to enhance your pump’s performance over time.

Comments are closed.