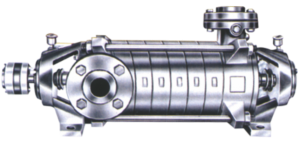

JCBFP Series

CENTRIFUGAL HIGH PRESSURE PUMP

The JCBFP Series of JEE Pumps consists of Centrifugal High-Pressure Multi-Stage Pumps. These pumps are embedded with several impellers, which help in generating very high pressure. Hence they are extensively used in industrial applications demanding high pressure. The pump is designed to operate stably even with such a high-pressure load. The JCBFP Centrifugal High-Pressure Multi-Stage Pumps can also withstand temperatures up to 140°C making them more versatile. In addition, these pumps are comparatively more economical and allow customizing the pressure levels.

Pump Construction

The pump design is multistage construction with verticle split casing & intermediates, allowing for high head discharge. It is a horizontal pump with a stage tie attached with suction & discharge brackets through rods. The pump base is cast integral with suction and discharge brackets.

Impeller has axial thrust balancing and is die-casting with a very smooth finish to provide the highest efficiency level. In addition, impellers can be made out of any material depending on the customer’s process requirement.

Heavy-duty ball bearings that are capable of carrying thrust load in either direction are used in pump design. In addition, grease-lubricated bearings are used, which ensure a longer life for the pumps.

Un-cooled soft-packing are provided with a sealing connection on the suction side of the pump. For higher pumped media temperatures, a stuffing box can be provided with a cooling cover which facilitates external cooling.

All the flanges are faced and drilled as per DIN standards.

The pump is designed to drive by an electric motor through flexible coupling. The direction of rotations is perceived as clockwise when viewed from the driver’s end. As a result, suction is nearer to coupling and discharge at the other end.

Features

- Designed For High-Pressure Industrial Applications

- It Comes With The Option Of Cooling Cover Stuffing Box

- Robust Pump Construction For Stable Operations Even At High Pressure

- Can Handle Water And Liquids At High Temperature

- Impeller Material Can Be Varied To Suit Customer Applications

- Proves To Be Very Economical And Efficient For High-Pressure Applications

Applications

Our JCBFP Centrifugal High-Pressure Multi-Stage Pumps can handle a large volume of water at high pressure on continuous duty. Hence they are used for cooling water applications where an effecient steady water supply is to be provided.

Power plants need high-pressure pumps for various applications like boiler feed cycles, circulating water, condensate system, fuel injection and many more. Our JCBFP Centrifugal High-Pressure Multi-Stage Pumps are designed to handle all such requirements.

The firefighting system needs a heavy-duty pump to feed water at high pressure. This is something that our JCBFP Centrifugal High-Pressure Multi-Stage Pumps can execute efficiently and reliably. Hence the JCBFP pumps are widely used in fire fighting systems.

JEE Pumps’ JCBFP Centrifugal High-Pressure Multi-Stage Pumps can generate a high amount of pressure and hence can displace liquids, especially water, to a distance. Therefore these pumps are used for irrigation supply.

Mining industries need high-pressure pumps for drilling or pulling out wastewater. JEE Pumps’ JCBFP Centrifugal High-Pressure Multi-Stage Pumps can execute these tasks cost-effectively and reliably and are used in mining industries.

Our JCBFP Centrifugal High-Pressure Multi-Stage Pumps can push water and other liquids to a great height. Hence these pumps are deployed in high-rise buildings for transporting water from the ground level to the top.

Copyright © 2024 JEE Pumps | All Rights Reserved. Website Designed & SEO By Webclick® Digital Pvt. Ltd. Website Designing Company India.