We are surrounded by technical marvels and innovations aimed at making the quality of our lives better. One such widely used but understated innovation is ‘Pumps.’ All industries and even most home appliances use pumps in some way or the other, be it for driving fluids or pumping gases.

A pump is a mechanical device that utilizes suction or pressure to drive liquids, compress gases, or force air. Pumps are often used in plumbing and irrigation systems, but they can also be used in conjunction with other machines, such as engines and compressors. Pumps come in various sizes and styles, each designed for a specific purpose.

How Do Pumps Work?

Pumps are basically simple devices that are used to move fluids by mechanical means. Pumps come in many different forms, but all share the common goal of moving fluid from one place to another. Pumps can be used for various applications based on need, including moving water, air, gasoline, and other liquids.

Pumps work by creating a vacuum which is used to push or pull liquids or gasses. Different types of pumps have different ways of working; however, what remains common is creating a difference in pressure points which creates suction. The liquid or the gas will always move from high to low pressure.

The type of pump you use will depend on the job you need it to do. For example, a small hand-held pump is typically used to inflate a tire, while a much larger pump is necessary to move water through a plumbing system. There are many different types of pumps, each with unique features and benefits.

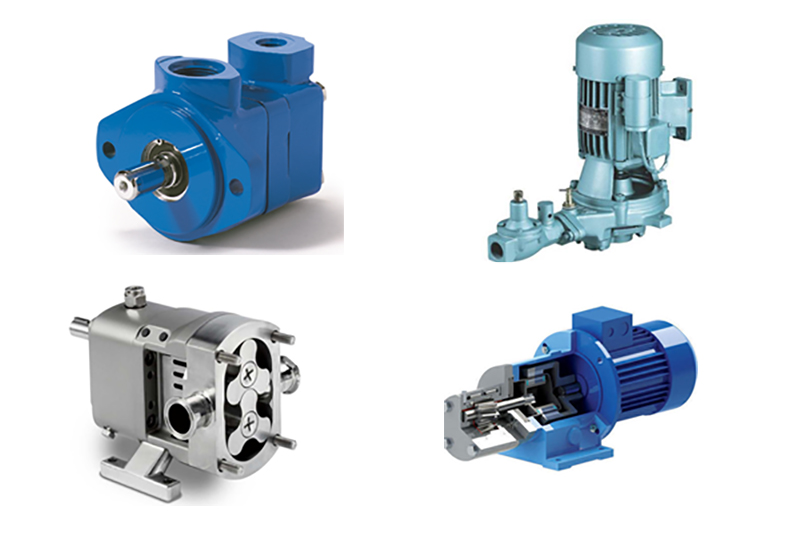

What Are The Major Types Of Pumps?

1. Centrifugal Pumps:

These pumps use centrifugal force to move fluid through a piping system. Centrifugal pumps are typically used for large-scale applications such as irrigation or water treatment where fluid volume is very high.

2. Diaphragm Pumps:

These pumps use a diaphragm to move fluid by reciprocating motion. They are also known as AOD pumps as they are operated pneumatically. Diaphragm pumps are often used in medical and chemical applications where precision is more needed than volume.

3. Gear Pumps:

Gears are widely used for transmitting motion, and the same is the case with gear pumps as they move fluid by meshing the teeth of two gears together. Gear pumps are rotating positive dislocation pumps that are commonly used in industrial applications to push thick liquids like fuel and oils.

4. Hand Pumps:

These pumps are operated by hand, typically using a handle or lever. Hand pumps are often used for small-scale applications such as transferring water from one container to another. They are highly portable and can be operated without electricity.

5.Hydraulic Pumps:

The pump that converts mechanical energy into hydraulic energy is called a Hydraulic pump. These pumps work on the fundamental Pascals law and are common in everyday applications. For example, hydraulic pumps are commonly used in construction and agricultural equipment.

6. Jet Pumps:

These pumps use jet propulsion to move fluid through a piping system. It is a self-priming pump with no movable parts. Friction losses make it less efficient than centrifugal pumps. Jet pumps are typically used for large-scale irrigation or water treatment applications.

7. Lobe Pumps:

These pumps move the fluid by displacement using two or more rotating lobes. They are known for being efficient, reliable, and hygienic. This is why Lobe pumps are commonly used in the food and beverage industry.

8. Magnetic Drive Pumps:

These pumps use magnets to move fluid by attraction and repulsion science. They are sealless pumps, making them very efficient and also leakproof. Magnetic drive pumps are often used in medical and chemical applications to drive expensive or dangerous fluids.

9. Metering Pumps:

Metering pumps pump at a fixed volumetric flow rate. This means that they deliver a specific volume of fluid with each stroke. Metering pumps are commonly used in industrial applications where there is a need for precise volume pumping, like dosing plants.

10. Peristaltic Pumps:

Also known as a roller pumps, these pumps use peristaltic motion to move fluid by squeezing a tube. Given their operational merits, peristaltic pumps are often used in medical and chemical applications like pumping IV fluids, highly reactive chemicals, and even heart-lung machines to circulate blood.

11. Piston Pumps:

A positive dislocation pump uses a piston to move fluid by reciprocating motion. Piston pumps are commonly used in industrial and agricultural applications like water irrigation, where high and reliable pressure systems are needed.

12. Propeller Pumps:

These pumps use a propeller to move fluid by rotating motion. They are a high flow, low lift type device. This is why there are used in applications where high flow volume is needed with low head values, like water treatment and chemical plants.

13. Rotary Pumps:

Operating on the positive displacement principle, rotary pumps deliver a fixed fluid volume for each revolution. These pumps are self-priming and deliver fixed capacity irrespective of pressure. They are used in the oil and gas industry, handling fluids with high viscosity.

14. Screw Pumps:

A scew pump uses a single or multiple screw arrangement to move fluids across its axis line. It is one of the most ancient pumping mechanisms. Screw pumps are often used in industrial applications such as fuel injection, oil burners, and hydraulics.

15. Solar Pumps:

These pumps use solar power to move fluid by photovoltaic action. The pump type used in this arrangement may vary based on need, but the power source remains the Sun. Solar pumps are typically used for small-scale applications such as watering a garden or filling a swimming pool.

16. Submersible Pumps:

The main USP of submersible pumps is that the pump assembly is submerged in the fluid to be pumped. They can use a screw mechanism or centrifugal mechanism to drive the fluid. Submersible pumps are often used in agricultural, water, and sewage applications.

17. Sump Pumps:

These pumps are used to remove water accumulated in a sump pit. Sump pumps are commonly used in residential and commercial applications and water drainage mechanisms. Sump pumps can be either pedestal or submersible based on the application need.

18. Transfer Pumps:

Transfer pumps are used to transfer fluid from one container to another, thereby serving the primary motive of pumps. They create the right amount of suction which helps move the fluid from one point to another. Transfer pumps are often used in industrial applications like fuel transfer and water and oil displacement.

19. Trash Pumps:

These pumps are used to remove water that contains solids or debris. Trash pumps are commonly used in construction and sewage applications. They use the centrifugal pumping mechanism and help separate the waste from water.

20. Vacuum Pumps:

The pumps that use vacuum pressure to move fluid by displacement are called Vacuum pumps. Vacuum pumps are often used in medical and scientific applications, given their ability to pump at high pressure precisely.

Whenever you are talking about pumps, you would come across various names that have been covered above. Please note that the above list is not classified as per their working or application but rather is compiled to give you a fair idea about the different types of pumps, their working, and application.

While sourcing pumps, make sure that you choose the right type of pump based on the application. All major pump solution providers would be able to provide you with the above type of pumps. However, you should be careful choosing your pump solution partner and opt for a reputed organization with an excellent track record in quality, reliability, and after-sales service.